Advanced Results

1. Synthesis of fullerenes, fullerene derivatives, and other nanomaterials

|

|

|

|

Self-blown plasma stream in free space and |

|

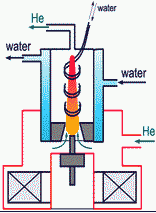

We developed a technique and fabricated a setup for atmospheric-pressure carbon-helium plasma synthesis of fullerenes, metal-carbon clusters, and carbon nanotubes.

Setup specification:

- Power, 12 kV

- Fullerene condensate output, 50 g/h

- Helium consumption, 1−4 l/min

- Weight, 30 kg

- Power supply, 380 V (three-phase network)

|

|

|

|

|

Nanotubes |

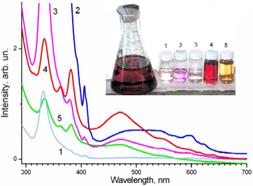

Electron absorption spectrum of the chromatographic fractions |

|

The setup comprises a power source, a synchronizer, and a plasma-chemical reactor with automated rod delivery and the nitrogen trap.

The carbon condensate contains

- 8−10% of fullerenes, including 80% of C60, 15% of C70, and 5% of higher fullerenes;

- 1−2% of metal-carbon nanodispersed (1−100 nm) clusters;

- 30−40% of single- and multiwalled carbon nanotubes (at embedding of 3d metal powders as catalysts).

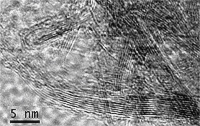

Introducing nickel during the carbon-helium arc plasma synthesis, we fabricated the carbon condensate and extracted multiwalled nanotubes 4−5 nm in diameter with 12−14 carbon layers and a small (3.34 Ǻ) inner central hole.

At our lab, a plasma technique for graphitization of refractory powders has been developed. We have learned to coat an aluminum-based sorbent with carbon for high-rate extraction of C60 (98%) and C70 (87%) after one separation stage.

During the synthesis, a co-product, turbostratic graphite containing nanotubes, is condensed on one of the electrodes. This material is energy-saturated. We found that the combustion wave velocity at the formation of titanium carbide by the self-propagating high-temperature synthesis exceeds the combustion rate in case of using other graphite modifications by a factor of 1.5−2.

2. Effective technique for fabricating water-soluble fullerenols

We developed a new fullerene hydroxylation technique based on low-temperature burning out amorphous carbon and the use of a nanodispersed catalyst. The method allows us to extract fullerenes without using toxic solvents and yields fullerenols without alkaline impurities, thus ensuring high antioxidant properties of the former.

3. Simulation of the formation of fullerenes and fullerene derivatives in carbon-helium plasma

Based upon experimental results obtained, we developed a concept of the formation of fullerenes and their derivatives. We experimentally and theoretically demonstrated that a key role in this processes is played by electron concentration of carbon plasma. We showed that molecular assembly of fullerenes is implemented via attachment of a C2 cluster.

4. Atomic emission spectrometry

We designed an operating model of the setup for the high-sensitivity atomic emission spectral analysis of the elemental composition of powder and monolithic substances on the basis of an original light source (RF Patent): a stable plasma filament 2 mm in diameter. The small diameter eliminates the effect of self-reversed spectral lines.

We designed an operating model of the setup for the high-sensitivity atomic emission spectral analysis of the elemental composition of powder and monolithic substances on the basis of an original light source (RF Patent): a stable plasma filament 2 mm in diameter. The small diameter eliminates the effect of self-reversed spectral lines.

Fields of application: geology, metallurgy, ecology.

Powder samples are analyzed with the use of a device developed by us for sample delivery in amounts from several milligrams to several grams.

Specification:

- Discharge supply by the 66- or 44-kHz current; power supply 380 V (three-phase network)

- Electrode erosion 10−12 g/K; coefficient of variation 2%

- Detection limit 10-4−10-8%

- Plasma-forming gas (argon) consumption 1.5−6 l/min

- Powder sample weight from 1 mg to several grams

- Monolithic sample weight unlimited

5. Detection of fast periodic processes

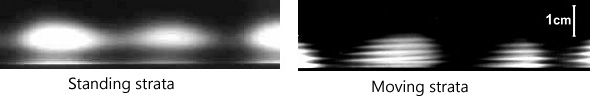

Our technique is grounded on synchronization of phases and frequencies of the discharge current and mirror rotation. The mirror rotation frequency and phase are taken as reference. The technique allowed us to detect for the first time standing and moving strata in a free-burning argon arc at atmospheric pressure.

6. Thermovacuum induction heating deposition of composite films

The original method for deposition of any refractory materials by thermal sputtering has been developed.